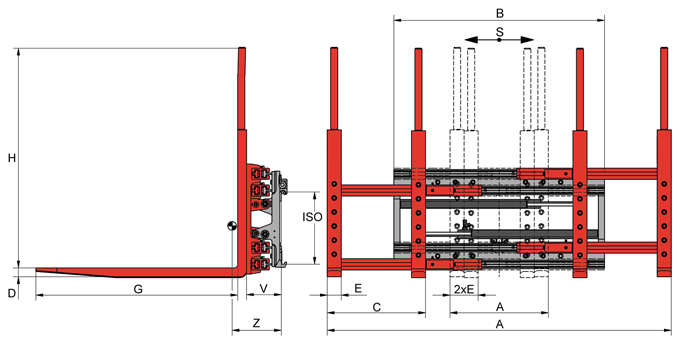

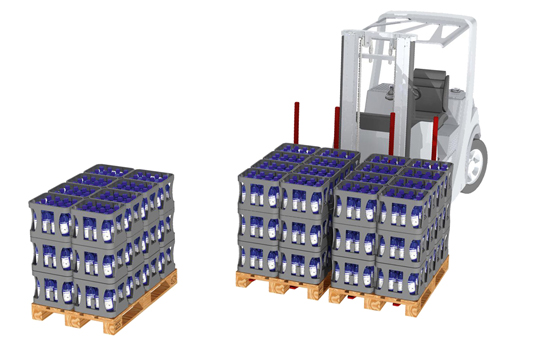

T429 Double Pallet Handler

with independent sideshift - with bolt-on forks - For 1 pallet or 2 pallets side by side, model 429-4 for 2 or 4 pallets - 2 hydraulic functions

The simple construction of KAUP Double Pallet Handler T429 with visibility improved design ensures a clear view through and over the attachments to the fork tips and load. The solid construction from T-profiles and C-profiles ensures stability and long operating hours with extended intervals between servicing and a minimum of required maintenance.

- Double Pallet Handler for heavy duty tasks

- Excellent visibility conditions

- Good residual capacity

- Screw-on forks serially

- Synchronized for quicker working speeds

- Independent sideshift serially

- Optional: single control of seperate fork pairs - adjustment of opening range to suit different types of pallets

| Model | Cap. kg | LCD mm | S mm | A mm | B mm | D mm | E mm | H mm | G mm | ISO | V mm | CofG Z mm | Weight kg | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1,5T429 | 1.600 | 600 | ±100 | 560-1.720 | 930 | 40 | 80 | 1.400 | 1.150 | 2 | 202 | 280 | 470 | |

| 1,5T429 | 1.600 | 600 | ±100 | 560-1.720 | 930 | 40 | 80 | 1.400 | 1.150 | 3 | 202 | 280 | 470 | |

| 2T429 | 2.200 | 600 | ±100 | 560-1.960 | 1.200 | 40 | 80 | 1.400 | 1.150 | 2 | 199 | 250 | 485 | |

| 2T429 | 2.500 | 600 | ±100 | 560-1.960 | 1.200 | 50 | 80 | 1.400 | 1.150 | 2 | 202 | 280 | 520 | |

| 2T429 | 2.500 | 600 | ±100 | 560-1.960 | 1.200 | 50 | 80 | 1.400 | 1.150 | 3 | 202 | 280 | 520 | |

| 2T429 | 2.500 | 600 | ±100 | 560-2.180 | 1.400 | 50 | 80 | 1.400 | 1.150 | 2 | 202 | 275 | 535 | |

| 2T429 | 2.500 | 600 | ±100 | 560-2.180 | 1.400 | 50 | 80 | 1.400 | 1.150 | 3 | 202 | 275 | 535 | |

| 2T429-4 | 1.250 | 1.200 | ±100 | 560-1.960 | 1.200 | 50 | 80 | 1.400 | 2.400 | 2 | 202 | 640 | 705 | |

| 2T429-4 | 1.250 | 1.200 | ±100 | 560-1.960 | 1.200 | 50 | 80 | 1.400 | 2.400 | 3 | 202 | 640 | 705 | |

| 2,5T429-4 | 1.600 | 1.200 | ±100 | 560-1.960 | 1.200 | 60 | 80 | 1.400 | 2.400 | 3 | 202 | 660 | 790 | |

| 3T429 | 3.200 | 600 | ±100 | 560-1.960 | 1.200 | 60 | 80 | 1.400 | 1.150 | 3 | 202 | 295 | 580 | |

| 3T429 | 3.200 | 600 | ±100 | 560-2.180 | 1.400 | 60 | 80 | 1.400 | 1.150 | 3 | 202 | 290 | 595 | |

| 3T429-2 | 5.000 | 600 | ±100 | 560-1.960 | 1.200 | 60 | 80 | 1.400 | 1.150 | 3 | 212 | 270 | 705 | |

| 3T429-2 | 5.000 | 600 | ±100 | 560-1.960 | 1.200 | 60 | 80 | 1.400 | 1.150 | 4 | 212 | 270 | 705 | |

| 3T429-2 | 5.000 | 600 | ±100 | 560-1.960 | 1.400 | 60 | 80 | 1.400 | 1.150 | 3 | 212 | 265 | 725 | |

| 3T429-2 | 5.000 | 600 | ±100 | 560-1.960 | 1.400 | 60 | 80 | 1.400 | 1.150 | 4 | 212 | 265 | 725 | |

| 3T429-4 | 2.500 | 1.200 | ±100 | 560-1.960 | 1.200 | 60 | 80 | 1.400 | 2.400 | 3 | 212 | 605 | 895 | |

| 3T429-4 | 2.500 | 1.200 | ±100 | 560-1.960 | 1.200 | 60 | 80 | 1.400 | 2.400 | 4 | 212 | 605 | 895 | |

| 3T429-4 | 2.500 | 1.200 | ±100 | 560-1.960 | 1.400 | 60 | 80 | 1.400 | 2.400 | 3 | 212 | 595 | 915 | |

| 3T429-4 | 2.500 | 1.200 | ±100 | 560-1.960 | 1.400 | 60 | 80 | 1.400 | 2.400 | 4 | 212 | 595 | 915 | |

| 4T429-4 | 4.600 | 1.200 | ±160 | 560-1.960 | 1.460 | 70 | 80 | 1.400 | 2.400 | 4 | 212 | 590 | 1.040 | |

| 6T429-4 | 6.000 | 1.200 | ±160 | 560-1.960 | 1.860 | 75 | 90 | 1.400 | 2.400 | 4 | 218 | 530 | 1.390 | |

| 6T429-4 | 6.000 | 1.200 | ±250 | 560-1.960 | 1.920 | 75 | 90 | 1.400 | 2.400 | 4 | 218 | 530 | 1.410 |

The newly designed Double Pallet Handler range T429C set new standards for Multi Pallet Handlers in lost load centre, residual capacity and visibility through and over the attachments to the fork tips and load. The practice orientated solid construction from T-profiles and C-profiles ensures highest stability and long operating hours with extended intervals between servicing and a minimum of required maintenance. At the same time the new Double Pallet Handler consumes 20% less energy.

with independent sideshift - 2 hydraulic functions

with independent sideshift - with bolt-on forks, for 1, 2 or 3 pallets side by side - 2 hydraulic functions

with independent sideshift - with bolt-on forks, for loading and unloading of up to 3 pallets from one side Lorries, Waggons etc.) - 2 hydraulic functions + solenoid valve

with independent sideshift - with bolt-on forks, Pallet handling lengthwise 800 x 1.200 mm for 4 or 6 pallets - 2 hydraulic functions

with independent sideshift - for 2 or 4 pallets side by side or 4 or 8 pallets - 2 hydraulic functions

Spare Parts

An extensive parts holding and efficient Parts Department is the key to the success of any maintenance operation. At our Cramlington facility, B&B maintains the highest viable spares and parts inventory, constantly reviewed and replenished from the original equipment manufacturers in the UK, Finland, Italy and Germany.

Field Service

With our team of qualified, experienced, factory-trained field service engineers with fully equipped vans based strategically throughout the UK, B&B is here to help you ensure that your new equipment is installed and maintained and any equipment failure and associated costly downtime are kept to an absolute minimum.

Workshop

B&B offers a complete refurbishment service - from minor repairs to total factory rebuilds of your existing fork lift truck attachments.

Kaup Multi Pallet Handlers

Kaup Multi Pallet Handlers